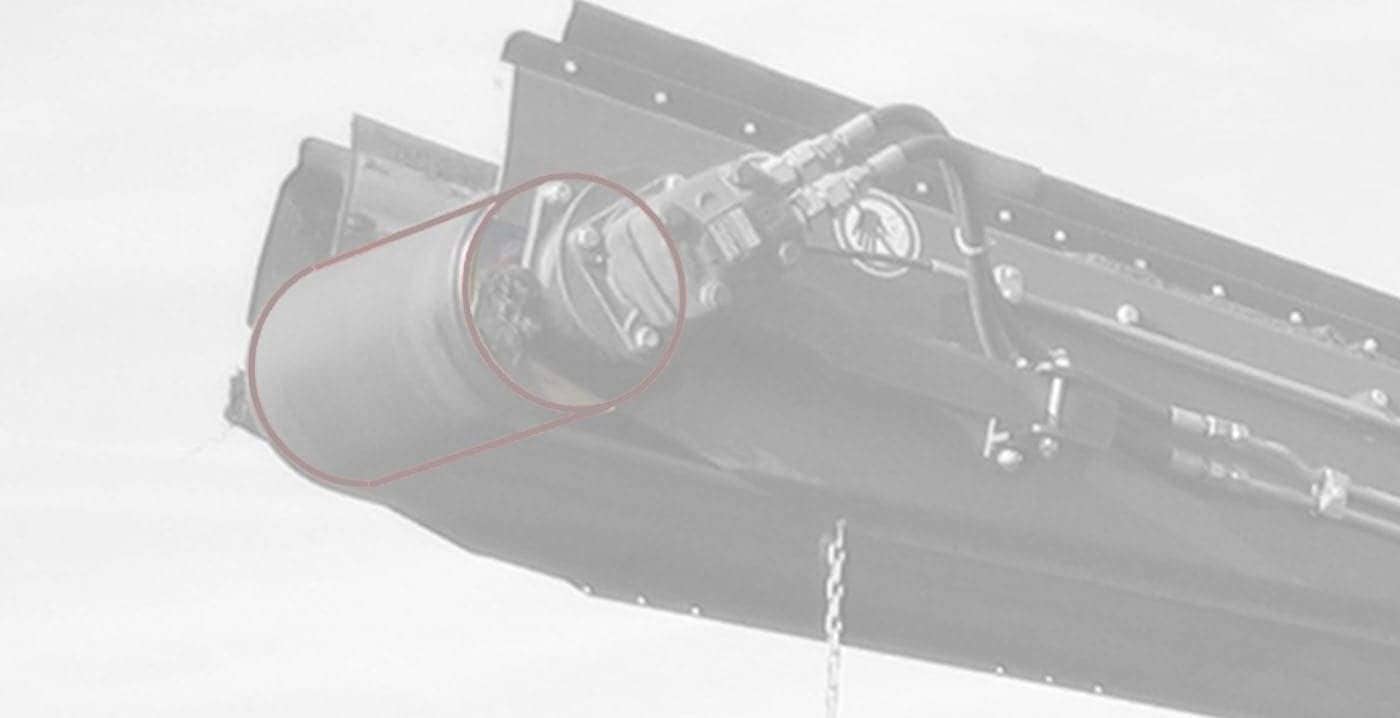

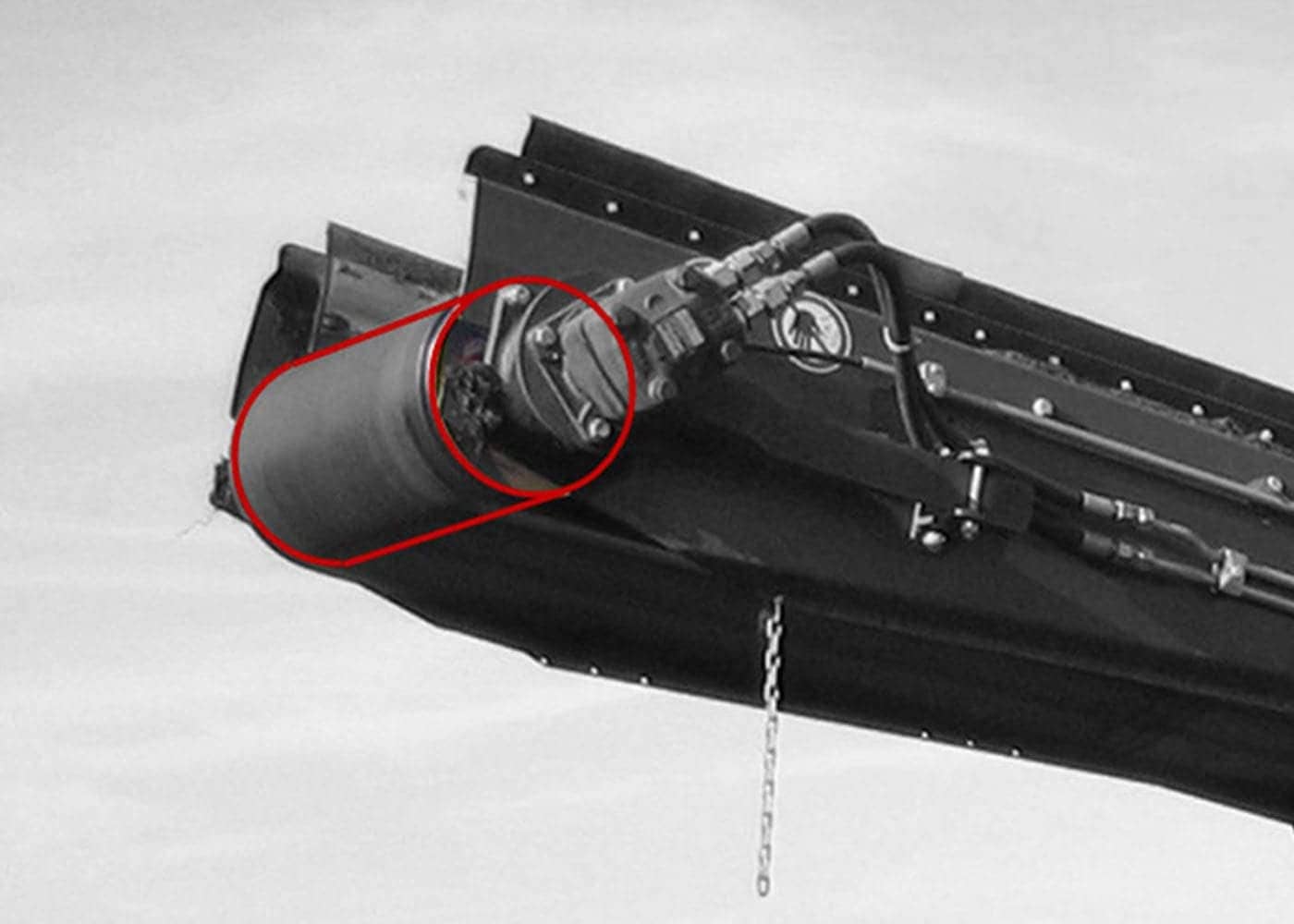

Magnetic Head Roller & Pulley

Made for any industry

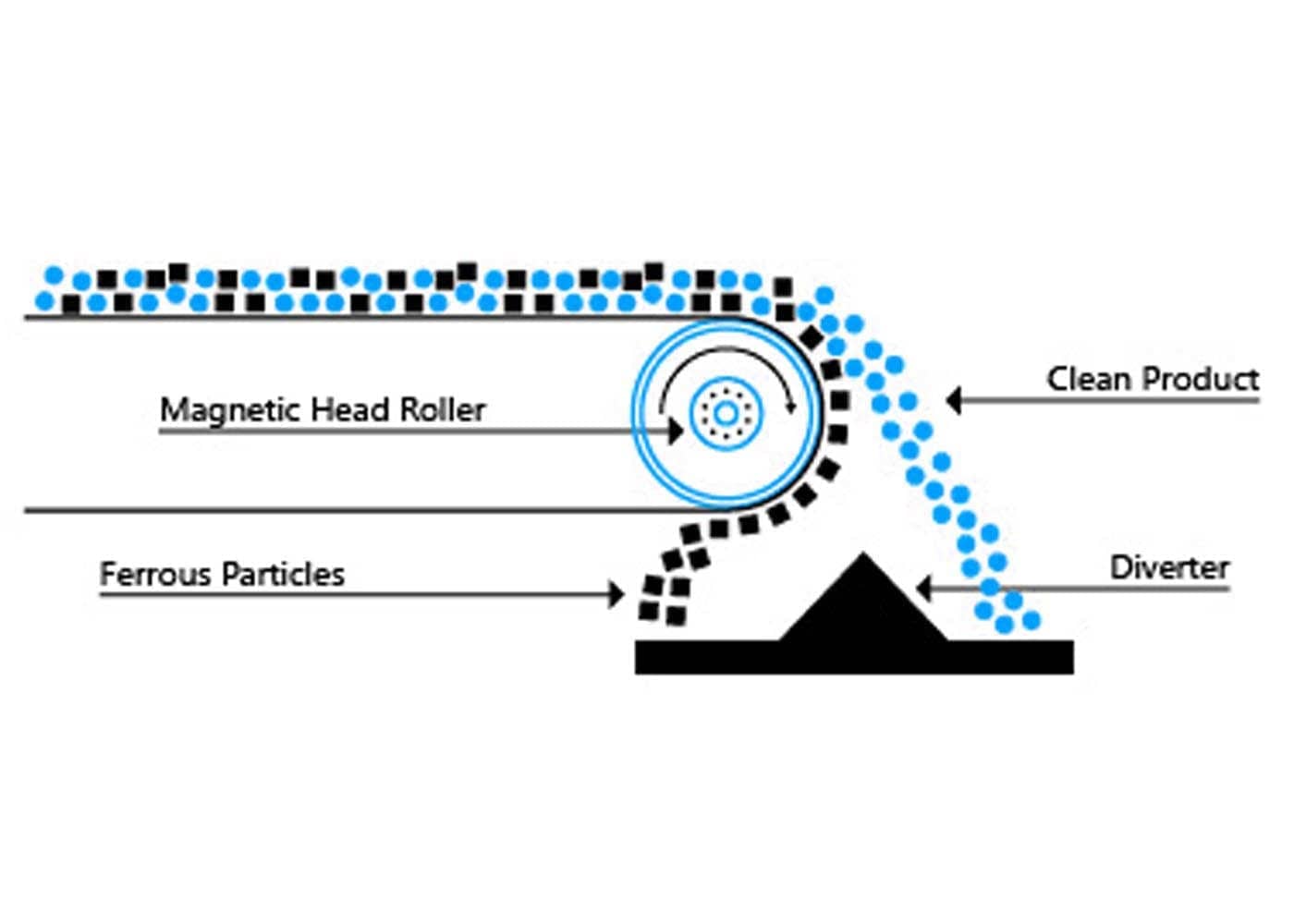

Magnetic head rollers are always placed at the head of your conveyor belt to separate ferrous particles, iron scrap and other ferrous magnetic objects from dry free-flowing materials such as powders, grains, recycling products, wood waste, rubber, plastics etc.

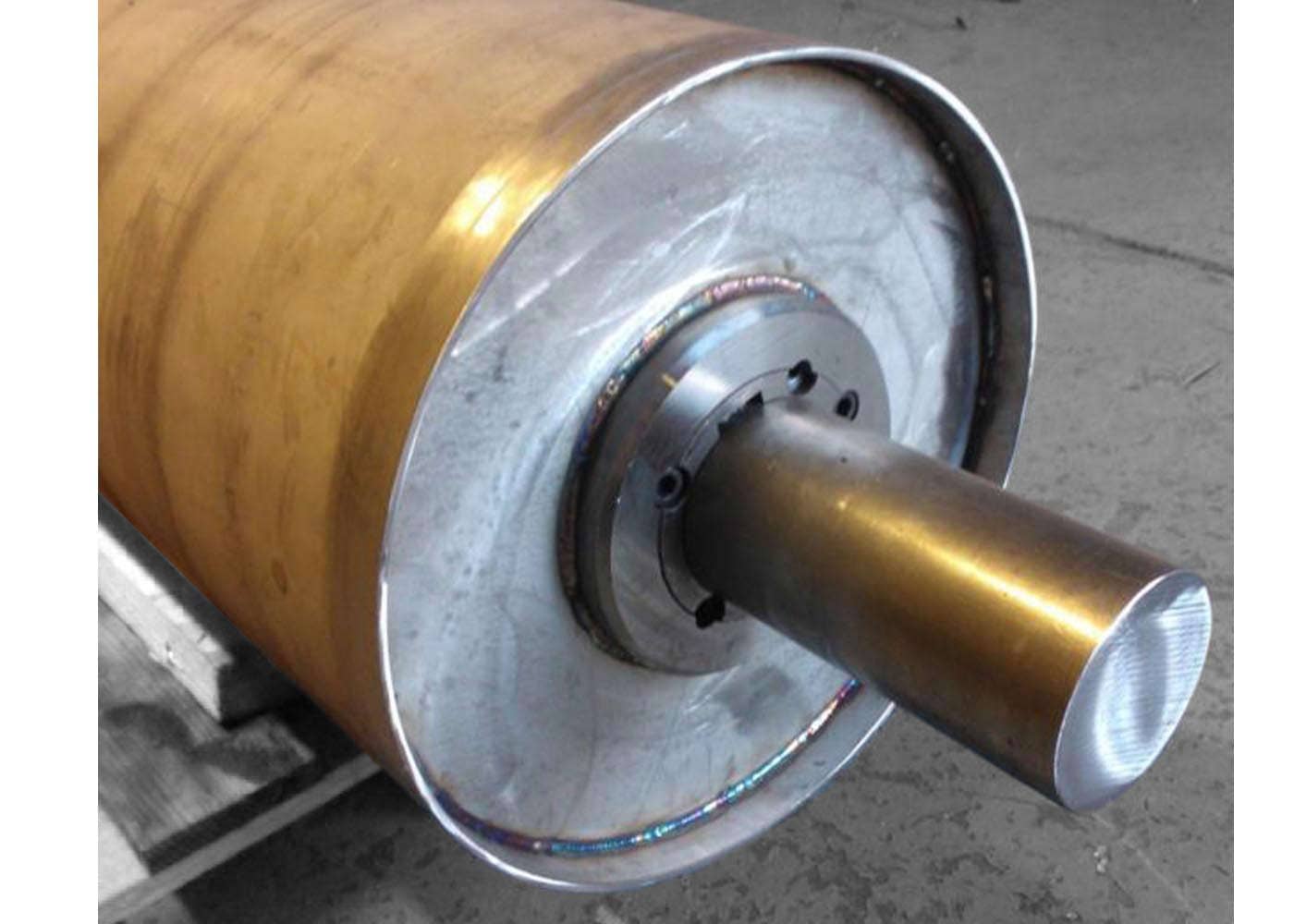

Permanent Magnet Power

Made from permanent magnets, head rollers can run without the need for electricity to run the magnetic field.

With options for Ceramic or the strongest Neodymium magnet head rollers have the ability to protect your product against ferrous contamination.

Ask the experts

Not sure what’s best for your line?

Get In Touch

Use the form below to inquire about this product. The more you tell us, the more we can help.